Ugira LT

Nerūdijančio plieno laikiklis (D10-12)

Nerūdijančio plieno laikiklis (D10-12)

Negalime šiuo metu pateikti informacijos apie atsiėmimo galimybę

KAS TAI?

KAS TAI?

Spalva: pilka.

Medžiaga: nerūdijantis plienas.

DAUGIAU INFORMACIJOS

DAUGIAU INFORMACIJOS

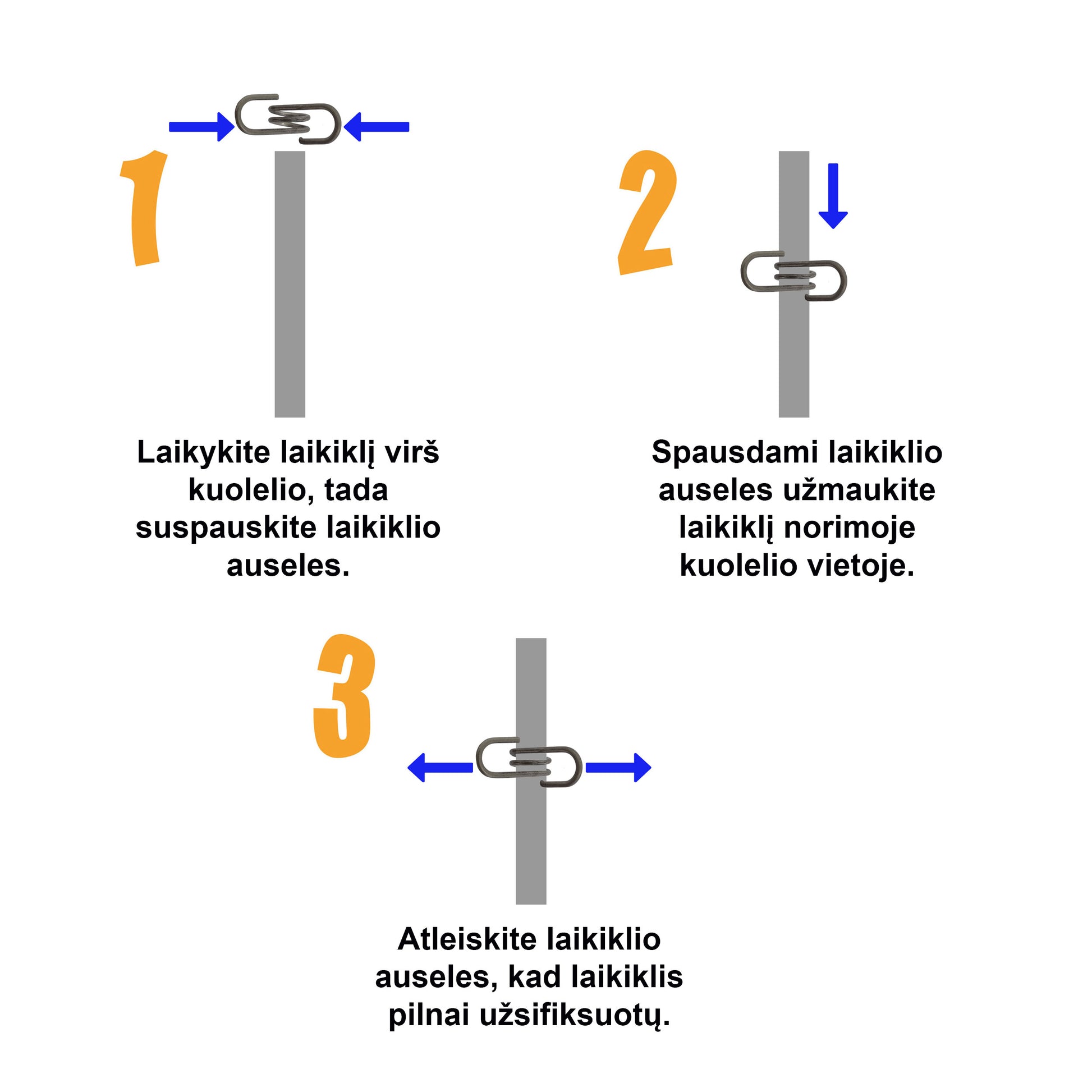

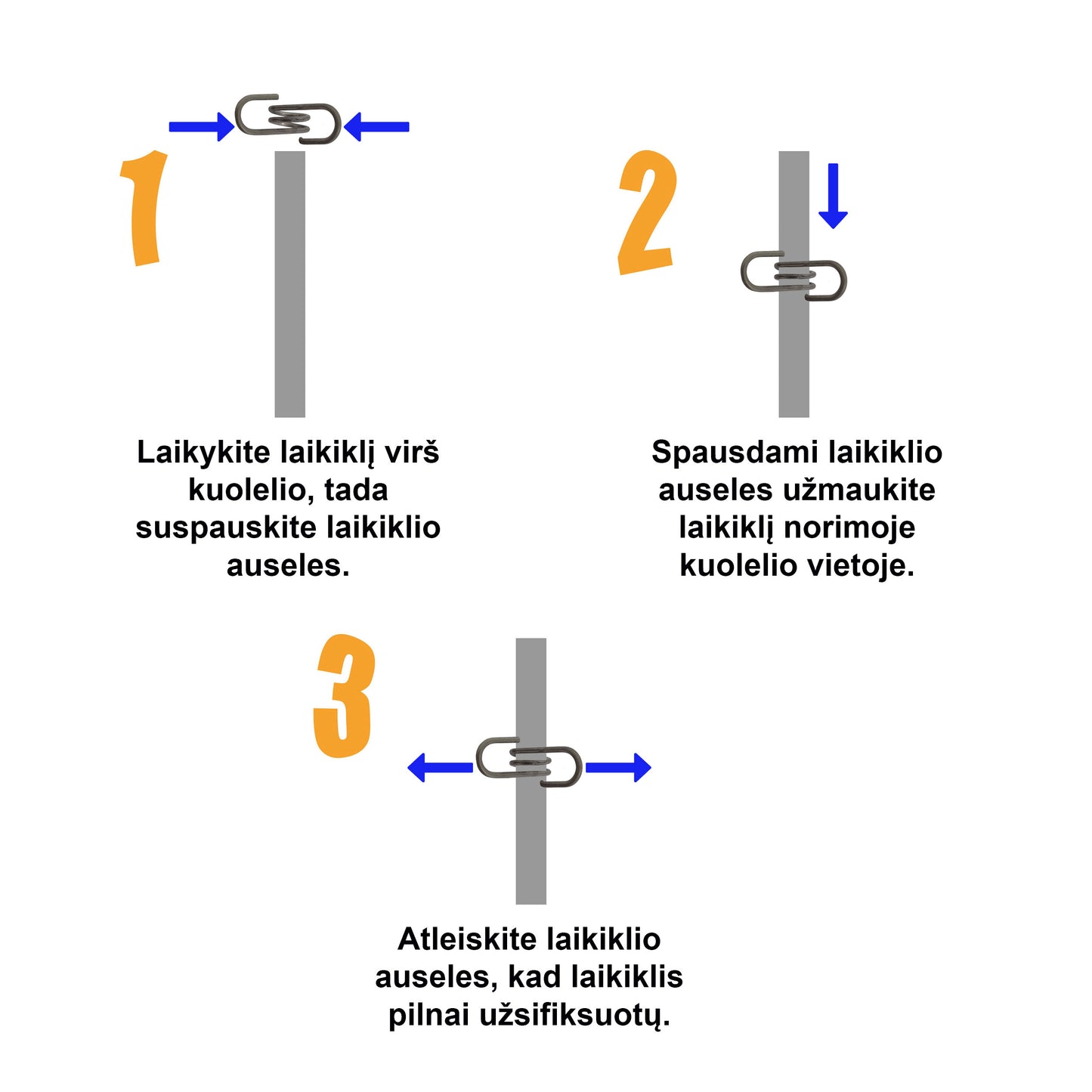

- Gali būti tvitinamas ant Ugira LT 10 mm ir 12 mm diametro kalibtuotų kuolelių.

- Nerekomenduojame šių laikiklių naudoti su rifliuotais kuoleliais. Dėl nelygaus kuolelio paviršiaus gali būti ypatingai sunku laikiklį užmauti.

- Tinkamas vielai ir juostai iki 10 mm pločio.

- Užapvalinti kraštai nepažeidžia vielos ar juostos.

- ĮSPĖJIMAS: laikikliai linkę tarpusavyje susikibti, turėkite tai omenyje nuimant juos nuo plastikinės juostelės :)

PRISTATYMAS

PRISTATYMAS

Užsakymai pristatomi naudojantis DPD kurjerių paslaugomis.

Pristatymo trukmė: 3-10 darbo dienų nuo užsakymo apmokėjimo.

Yra galimybė užsakymą atsiimti patiems adresu: Varpo g. 43, Šunskai, Marijampolės sav.

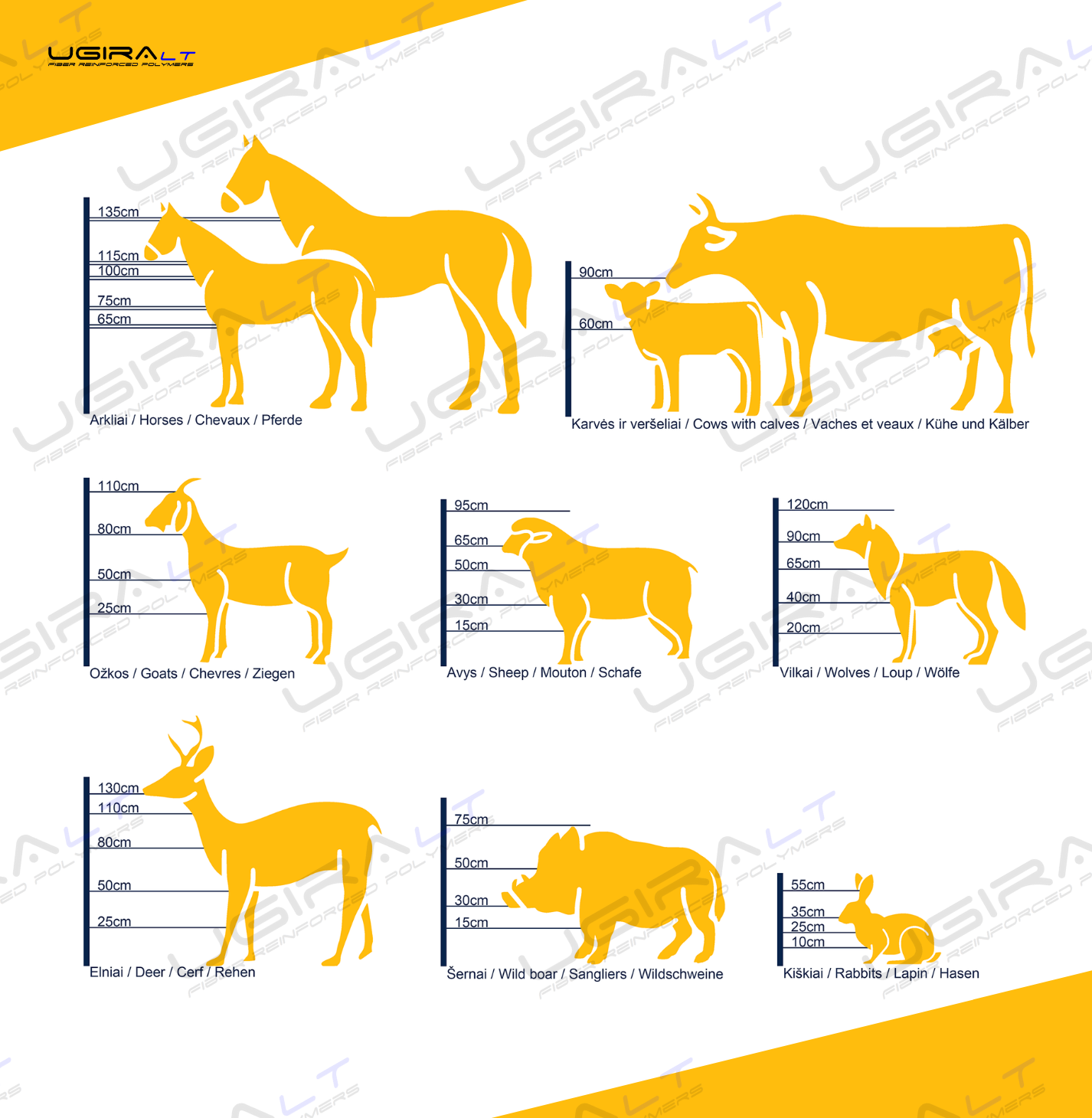

REKOMENDUOJAMI AUKŠČIAI

Kuolelius galime pagaminti Jūsų pageidaujamo ilgio, kad būtų lengviau išsirinkti Jums tinkamus, grafikuose pateikiame vielos ir juostos aukščius, kuriuos dažniausiai renkasi ūkininkai, priklausomai nuo gyvūnų, kuriuos norima aptverti, ar žvėrių, nuo kurių norima apsisaugoti.

Lentelėje žemiau, pateikiame kuolelių diametrus, kuriuos rekomenduojame rinktis, priklausomai nuo kuolelio ilgio.

Rekomenduojami aukščiai

|

Kuolelio aukštis virš žemės |

Bendras kuolelio kraštinėms ilgis |

Bendras kuolelio kampams ilgis |

Rekomend. kuolelio |

Rekomend. |

Dažniausiai tveriami gyvūnai, žvėrys |

|

1,40 m |

1,60 m |

1,70 m |

12 mm, 16 mm |

16 mm |

Žirgai, arkliai, stirnos |

|

1,30 m |

1,50 m |

1,60 m |

12 mm, 16 mm |

16 mm |

|

|

1,20 m |

1,40 m |

1,50 m |

12 mm |

16 mm |

Vilkai |

|

1,10 m |

1,30 m |

1,40 m |

10 mm, 12 mm |

12 mm, 16 mm |

Ožkos |

|

1,00 m |

1,20 m |

1,30 m |

10 mm |

12 mm, 16 mm |

Mėsiniai galvijai, karvės, avys |

|

0,90 m |

1,10 m |

1,20 m |

10 mm |

12 mm |

|

|

0,80 m |

1,00 m |

1,10 m |

8 mm, 10 mm |

12 mm |

Šernai |

|

0,60 m |

0,80 m |

0,90 m |

8 mm, 10 mm |

10 mm, 12 mm |

Triušiai, ūdros |

Bendras kuolelio kraštinėms ilgis lentelėje nurodomas darant prielaidą, kad į žemę smeigiasi 20 cm kuolelio, o kampams – 30 cm. Kiek giliai kuolelis turėtų būti smeigiamas, reikia įvertinti, atsižvelgiant į žemės kietumą. Dažniausiai į žemę kuolelis kraštinėms smeigiamas 15-30 cm, o kampams – 25-40 cm.