KODĖL VERTA RINKTIS KOMPOZITINIUS GAMINIUS?

-

Nelaidūs elektros srovei

Nelaidūs elektors srovei ir netrikdo elektomadnetinių laukų. -

UV stabilizuoti

Nekeičia savo savybių net po daug metų stovėjimo saulėje.

-

Stiprūs

Nulenktas kuolelis nesusilpnėja ir atsitiesia į pradinę padėtį iškart jį paleidus.

-

Lengvi

Patogu nešti net ir didesnius kiekius.

-

Atsparūs korozijai

Neįgeria vandens.

-

Šaltis, karštis neturi jokio poveikio

Nuo karščio nesuminkštėja ir nepasidaro trapūs nuo šalčio.

Suskleidžiamas turinys

Medžiagos prilavumai

- Mažas tankis – jo dėka šių medžiagų stiprio – svorio santykis yra gerokai pranašesnis nei plieno.

- Atsparumas kenksmingam aplinkos poveikiui.

- Gaminiai nelaidūs elektros srovei, netrikdo elektromagnetinių bangų ir nekeičia savybių veikiant elektromagnetiniam laukui.

- Mažas temperatūros poveikis, dėl to gaminiai demonstruoja didesnį matmenų stabilumą plačiame temperatūros diapazone.

- Didelė šiluminė varža – pavyzdžiui stiklo pluošto šilumos laidumas daugiau nei 100 kartų mažesnis nei plieno.

- Ypatingai paprastas transportavimas, apdirbimas ir montavimas.

Technologijos privalumai

Pultrūzijos būdu pagaminti profiliai atlaiko dideles ašines apkrovas.

Pultrūzija – tai nekintančio skerspjūvio profiliuočių gamybos technologija paremta nenutrūkstamu gamybos procesu, kurio metu:

- gaminį armuojantys pluoštai impregnuojami termoaktyvia derva;

- formuojamos gaminio geometrinės savybės – per kreipiančiąsias impregnuoti pluoštai nukreipiami į įkaitintą formą;

- formoje vyksta dervos kietinimas, kurio metu termoaktyviose dervose vyksta polimerizacijos procesas;

- suformuotas profiliuotis atvėsinamas ir pjaustomas.

Pultrūzijos proceso metu pluoštai nenutrūkstamai tempiami per visus aukščiau paminėtus gamybos linijos segmentus.

Naudojamos žaliavos

- Žaliavos - didelio stiprio ir tamprumo modulio pluoštai bei polimerinė termoaktyvi derva su specializuotais priedais.

- Norint pagaminti aukštos kokybės produktą – turi būti naudojamos aukštos kokybės žaliavos, todėl būtent tokias ir renkamės.

MŪSŲ GAMINIAI

-

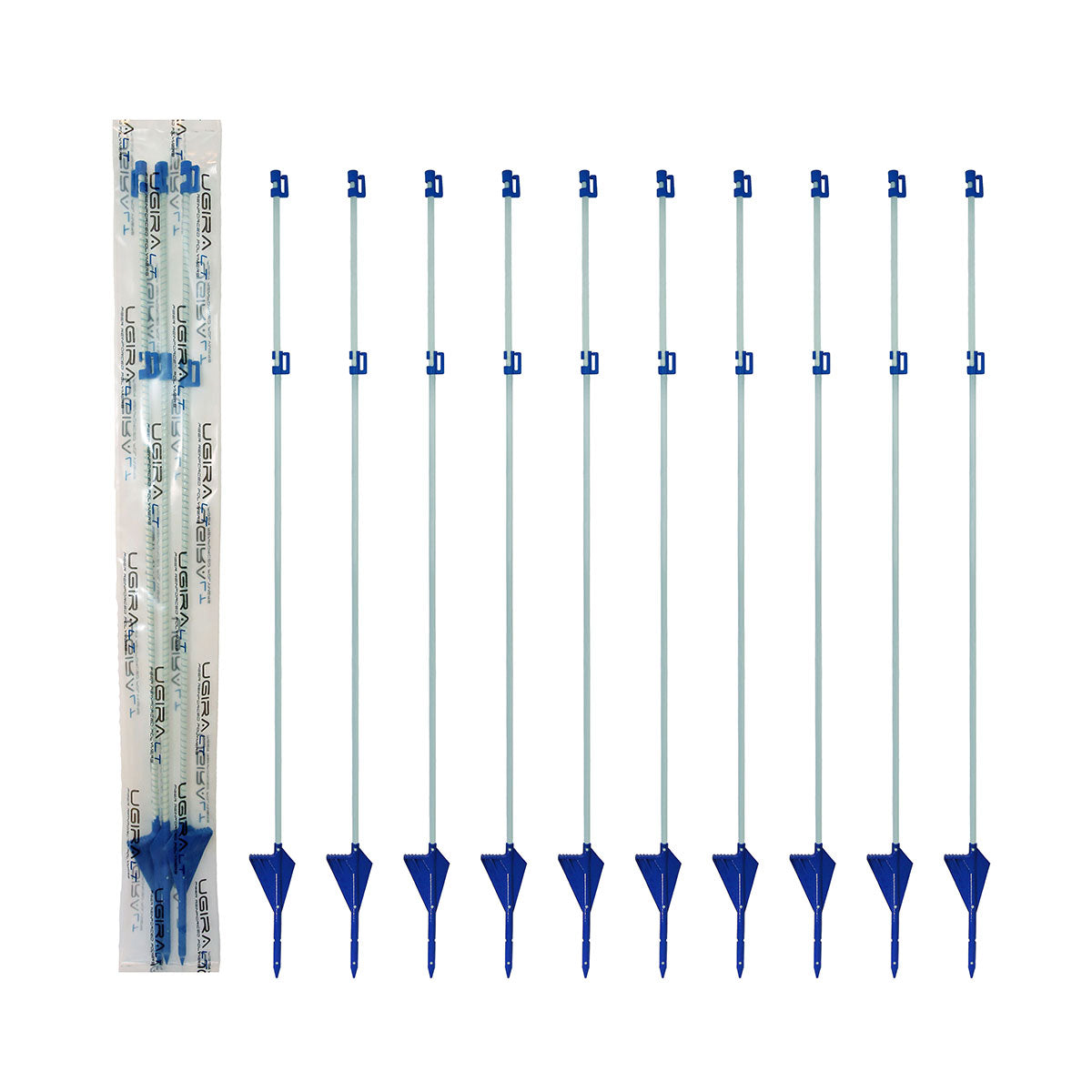

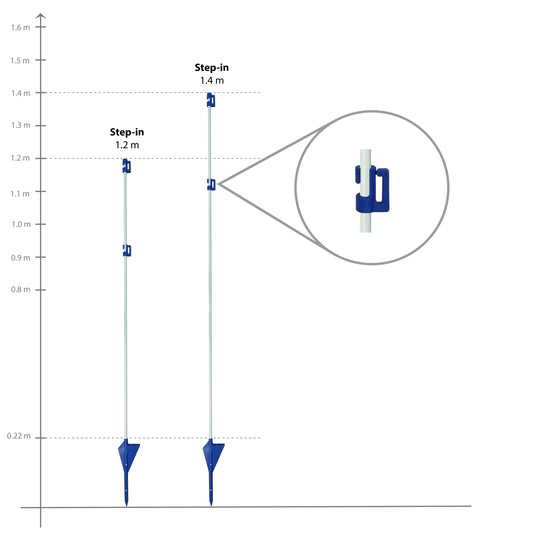

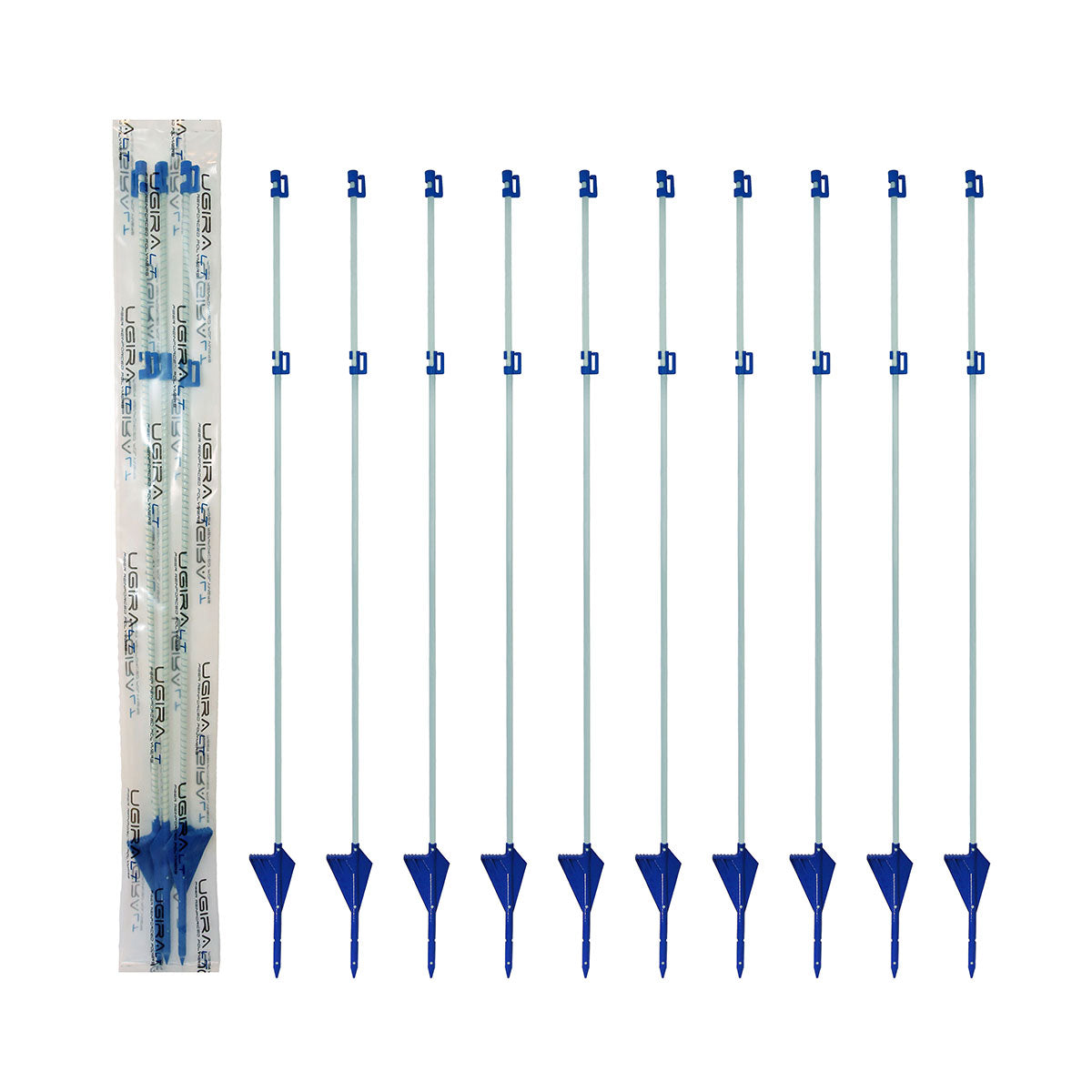

Kuoleliai elektriniam aptvarui

Nelaidūs elektros srovei Esant poreikiui, viela ar juosta gali būti apsukama tiesiai...

-

Stiklo pluošto armatūra

Didelis stipris Stiprumo riba tempiant 2 kartus didesnė nei S500 klasės plieno...

-

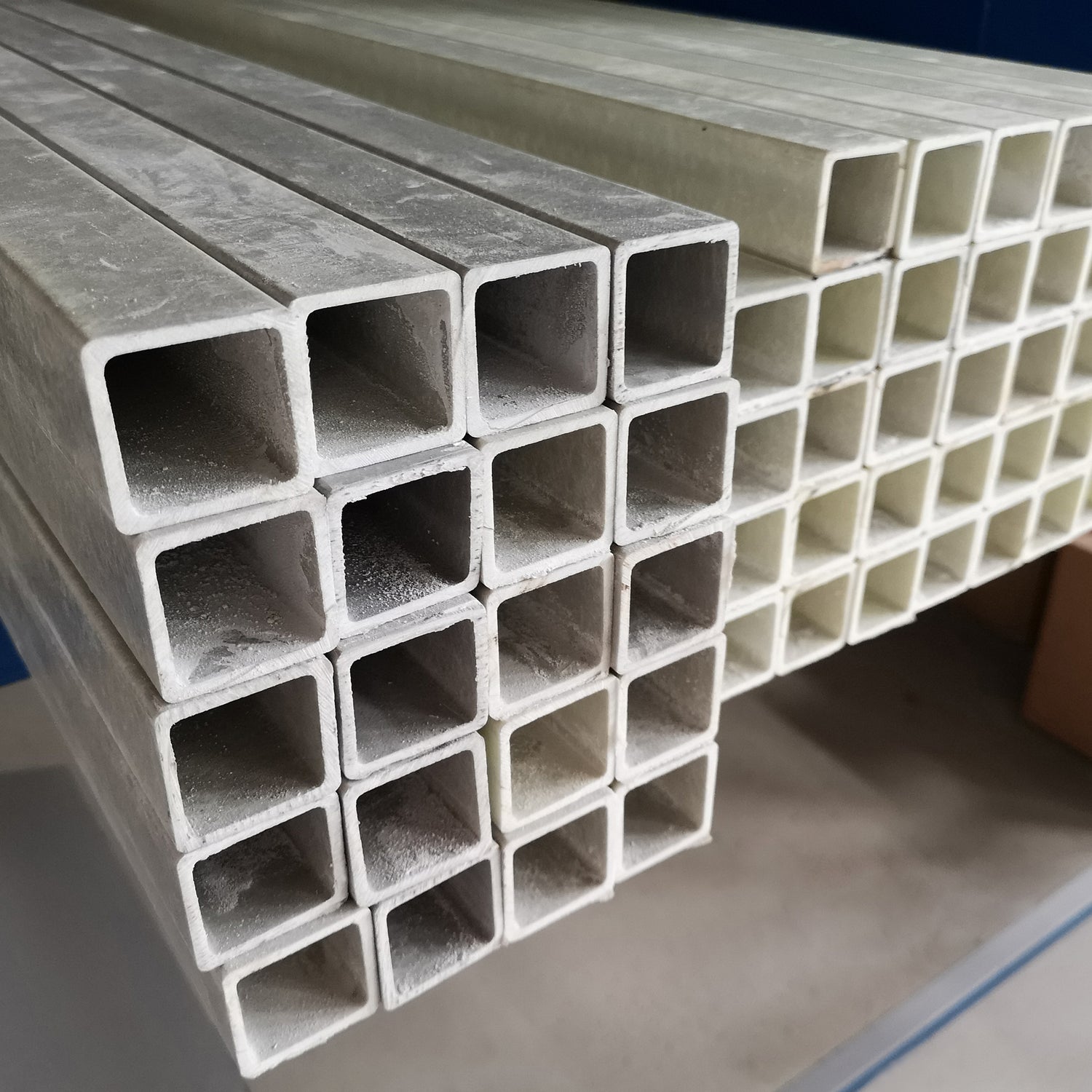

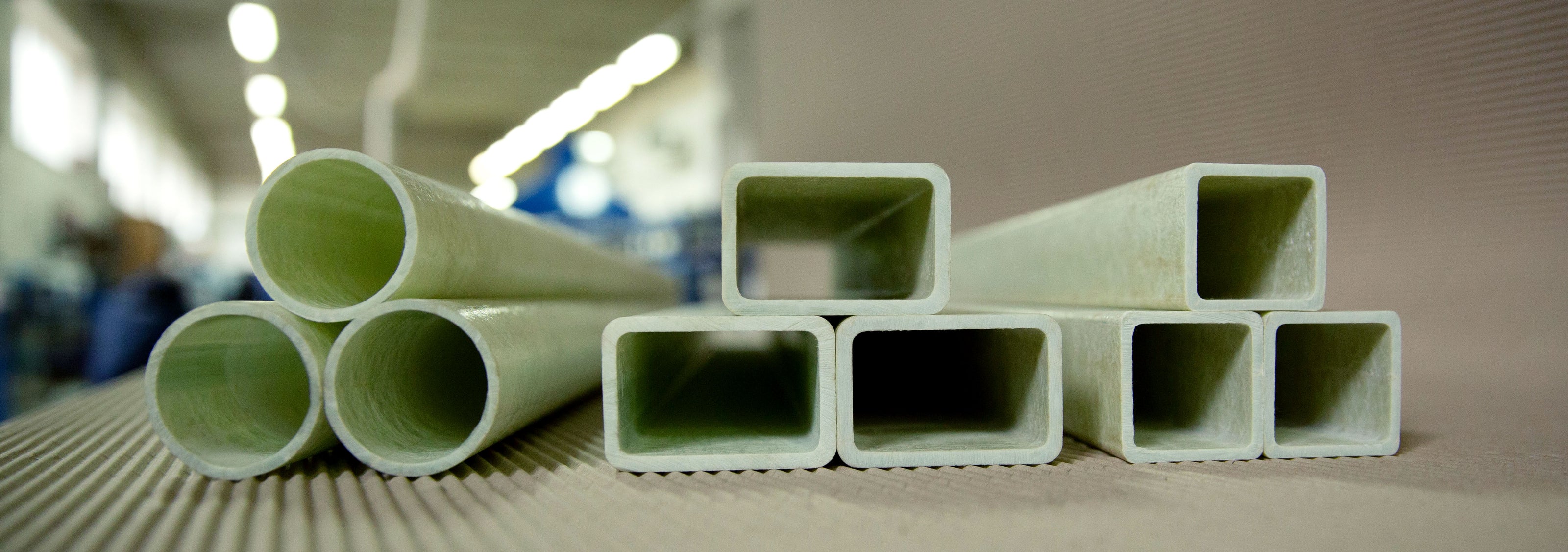

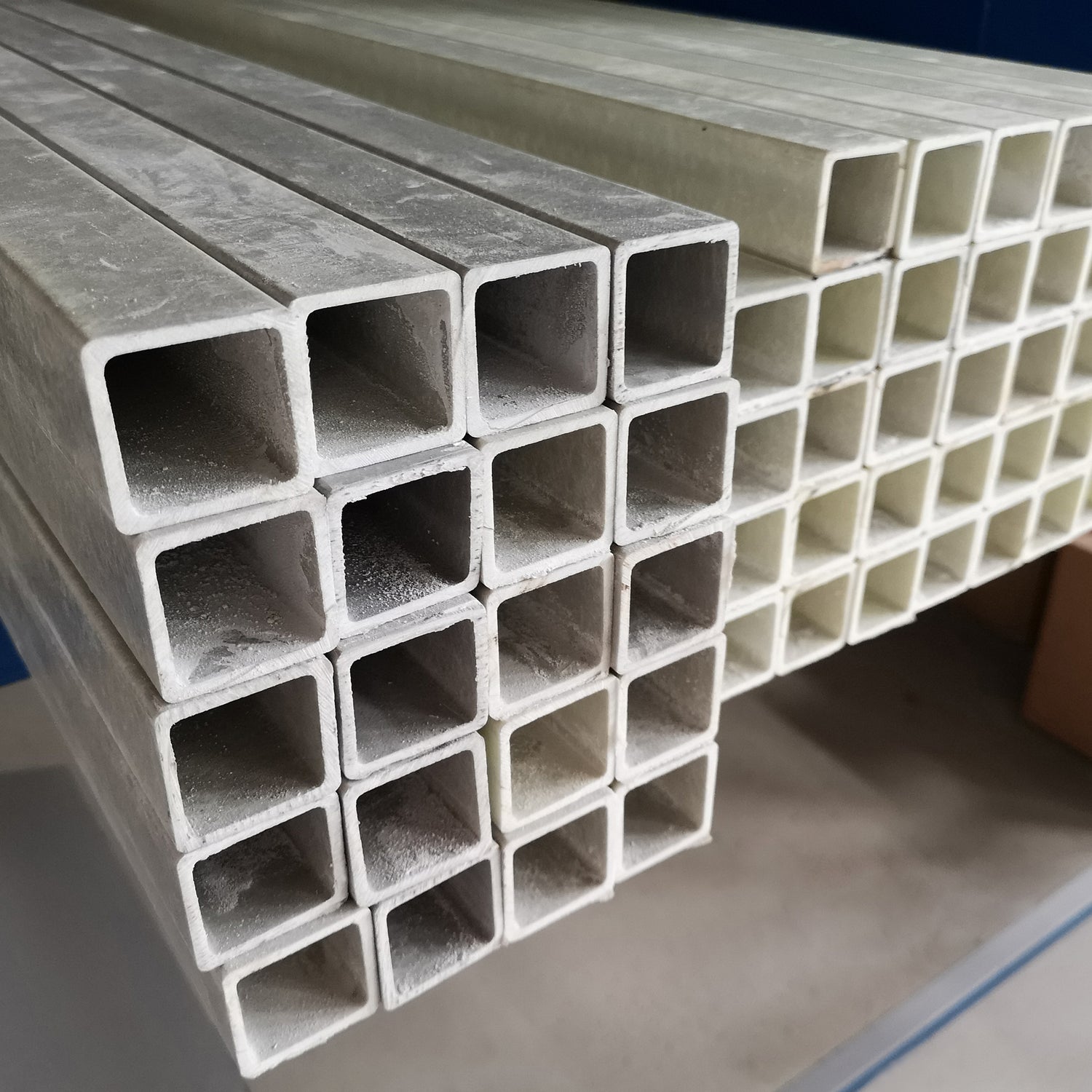

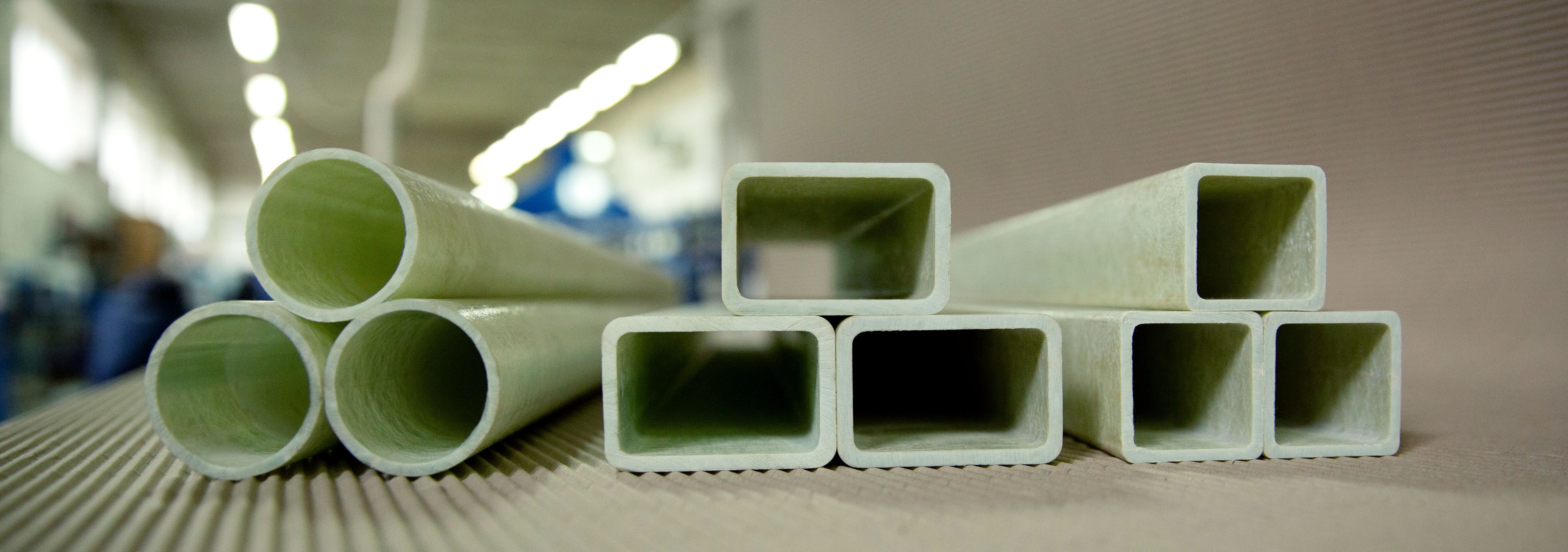

Kompozitiniai profiliai

Galime pasiūlyti stiklo pluošto profilius individualiai Jums pritaikytus pagal vieną ar kelis...

Stiklo pluošto armatūra

Puikus pasirinkimas grindų ir pamatų armavimui

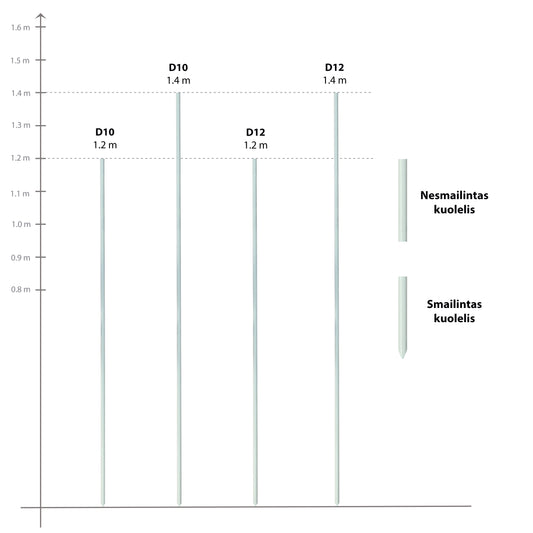

Stiklo pluošto kuoleliai

Tinka kilnojamiems ir stacionariems aptvarams

Stiklo pluošto profiliai

Stiprus, lengvas ir ilgaamžis plieninių, medinių ir aliumininių profilių pakaitalas

PIRKI DABAR

-

Tarpinis laikiklis vielai ir juostai (D10-12)

Įprasta kaina Nuo€0.11 EURĮprasta kaina -

Laikiklis vielai/juostai su veržle (D8-14)

Įprasta kaina€0.17 EURĮprasta kaina -

Kalibruotas stiklo pluošto kuolelis

Įprasta kaina Nuo€1.48 EURĮprasta kaina -

Stiklo pluošto laikiklis su papildomais standumo elementais (STV)

Įprasta kaina Nuo€3.52 EURĮprasta kaina -

Stiklo pluošto armatūra

Įprasta kaina Nuo€0.25 EURĮprasta kaina -

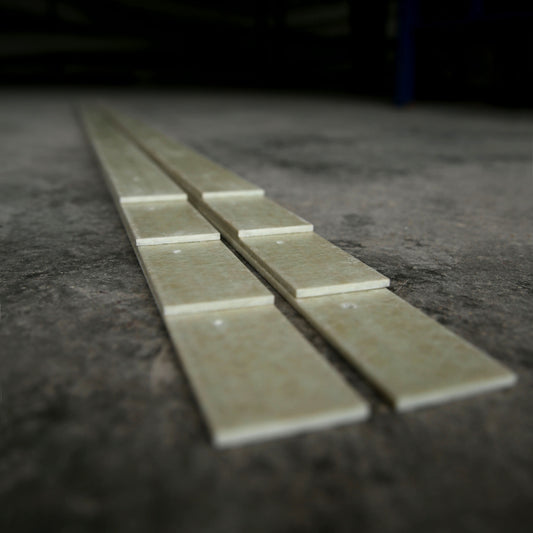

Stiklo pluošto juosta

Įprasta kaina Nuo€0.78 EURĮprasta kaina -

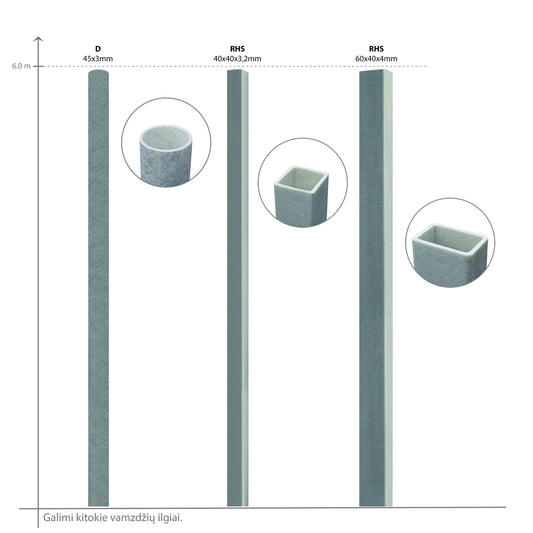

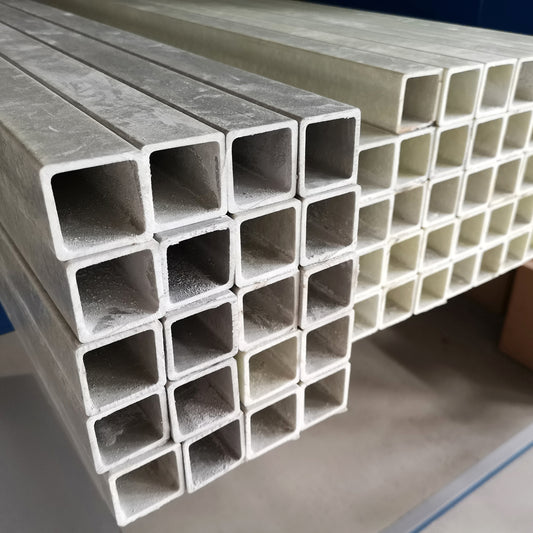

Stiklo pluošto vamzdžiai

Įprasta kaina Nuo€9.58 EURĮprasta kaina -

Rifliuotas stiklo pluošto kuolelis

Įprasta kaina Nuo€0.33 EURĮprasta kaina