WHY CHOOSE COMPOSITE PRODUCTS?

-

Non conductive

Non-conductive and completely transparent to magnetic and electromagnetic fields.

-

UV resistance

Does not change its features event after years standing in

sun. -

Strong

Under load flexes without weakening and springs back to

original position. -

Lightweight

Convenient to carry even bigger quantities.

-

Corrosion resistance

Does not absorb water.

-

Not affected by cold or heat

Does not become soft in heat or brittle in cold.

Collapsible content

Advantages of material

- Low density – therefore materials strength - weight ratiois far superior than steel.

- Resistance to harmful environmental impacts.

- Products are nonconductive to electric current, do not

disturb electromagnetic waves and does not change properties when are exposed to electromagnetic field. - Low temperature effects – products show increased

dimensional stability over a wide temperature range. - High thermal resistance - thermal conductivity more than 100 times less than steel.

- Extremely simple transportation, processing and installation.

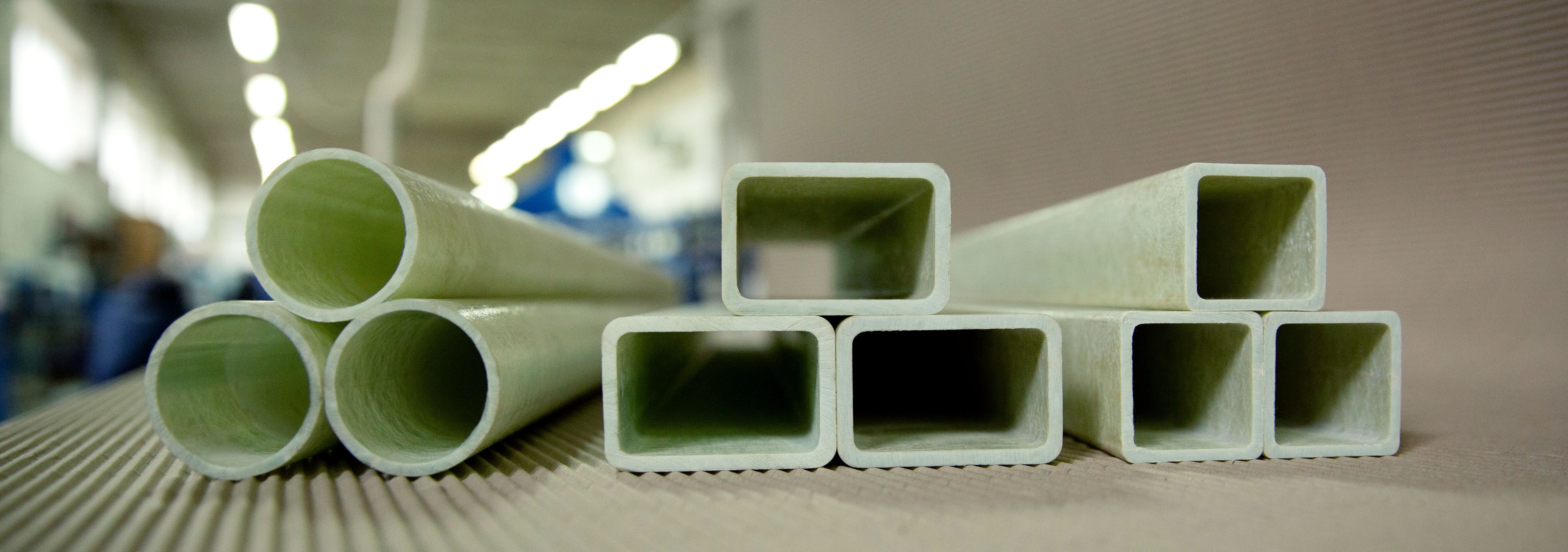

Advantages of technology

Pultruded profiles sustains high axial loads.

Pultrusion is a technology based on a continuous

manufacturing process in which:

- fibers reinforcing profile are impregnated with

thermo-active resin; - profile‘s geometry is formed by supplying impregnated

fibers to pre-heated form through pre-forms; - resin curing takes place in form – in thermoactive resins

polymerization process proceedes; - formed profile is cooled and cut.

In pultrusion process fibers are continuously pulled

through all the above-mentioned production line segments.

Raw materials

- Raw materials - high strength and elasticity modulus fibers

and thermo-active polymeric resin with specialized additives. - To produce a high quality product – high quality raw

materials must be used. Therefore are using top class raw materials from well

known manufaturers.

OUR PRODUCTS

-

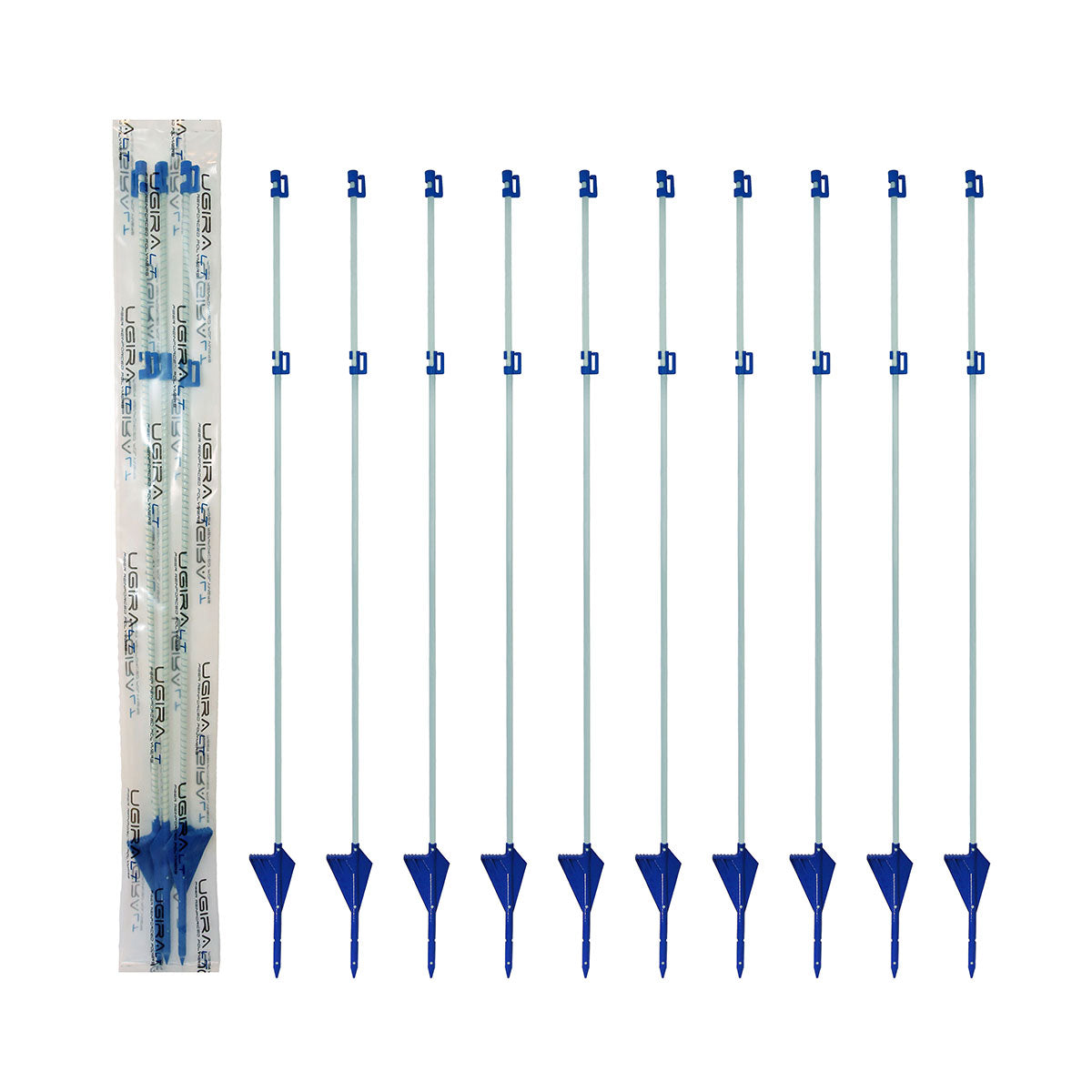

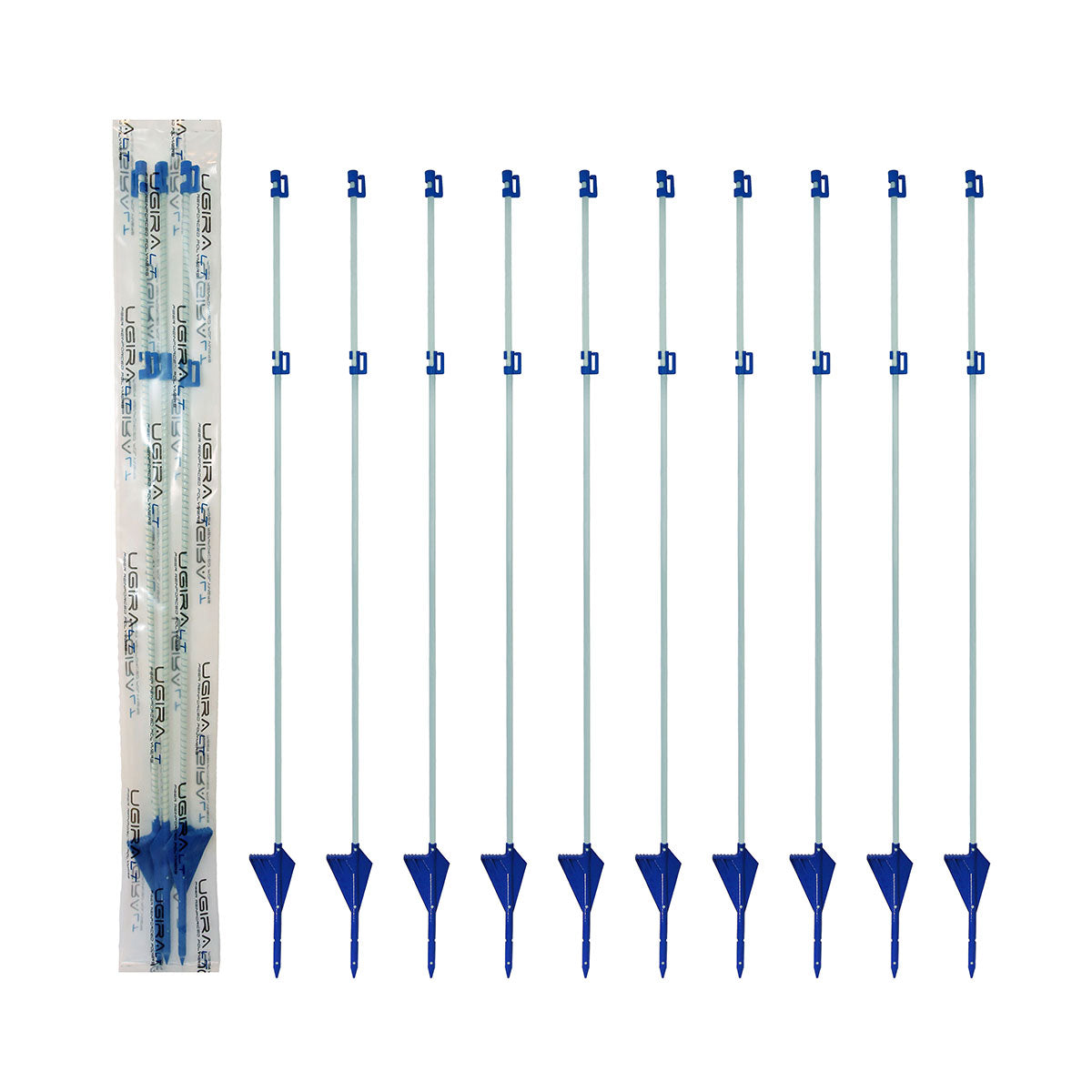

Posts for electric fencing

Nelaidūs elektros srovei Esant poreikiui, viela ar juosta gali būti apsukama tiesiai...

-

Fiberglass rebar

Didelis stipris Stiprumo riba tempiant 2 kartus didesnė nei S500 klasės plieno...

-

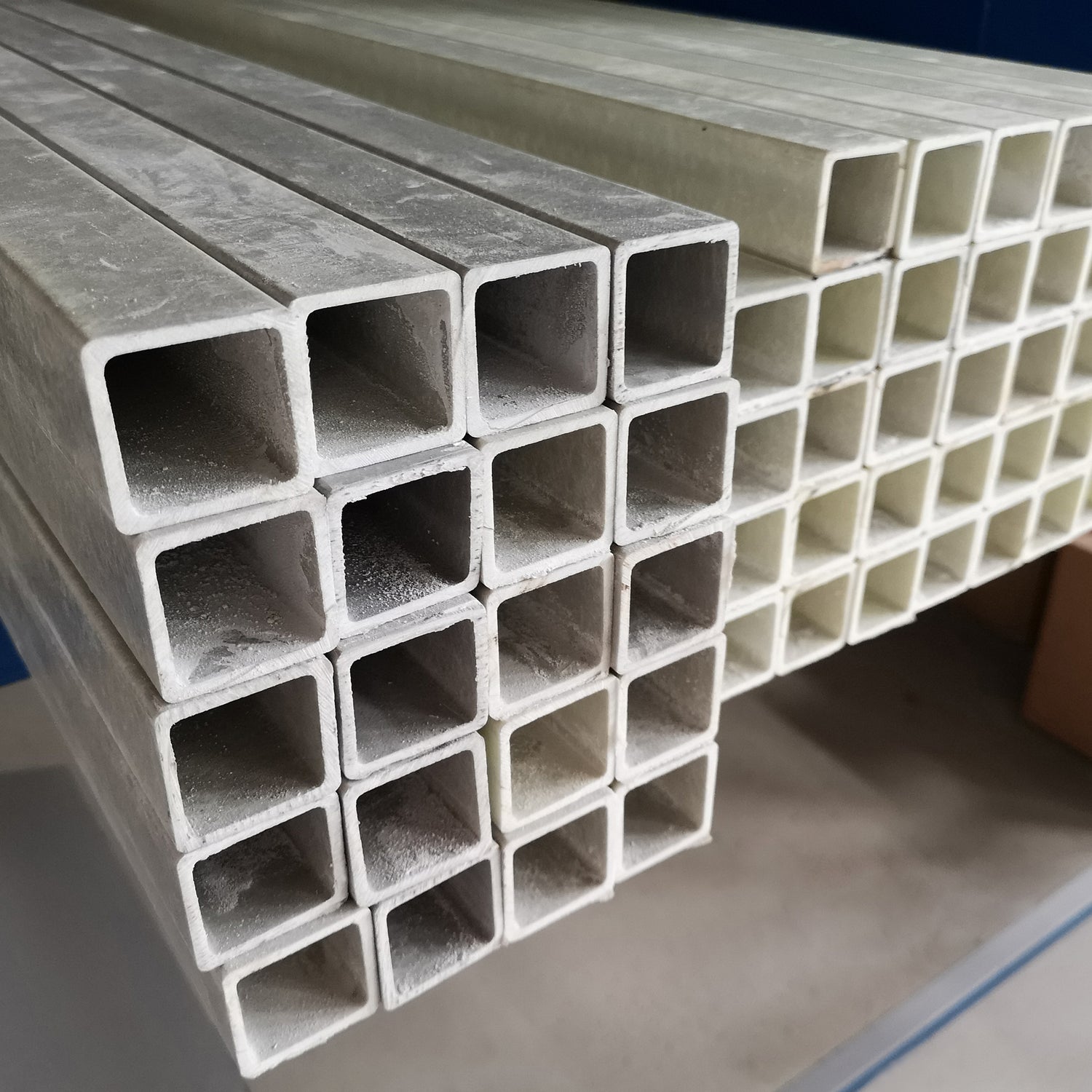

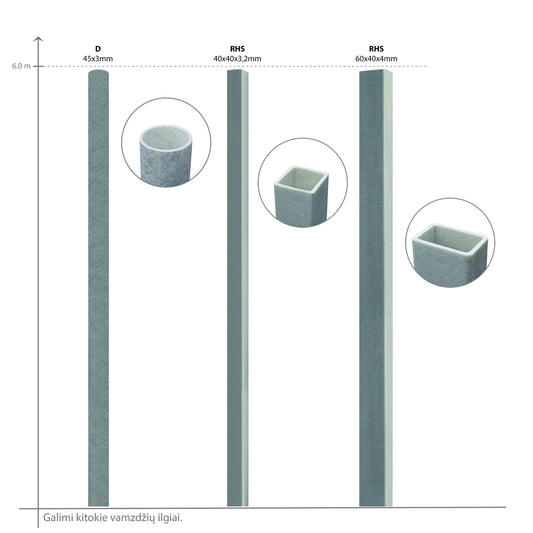

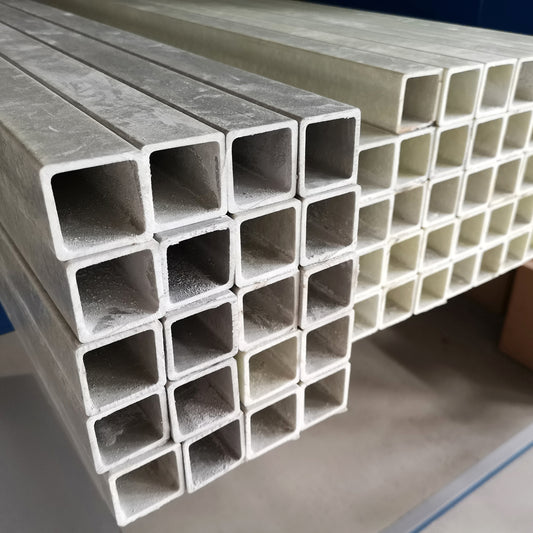

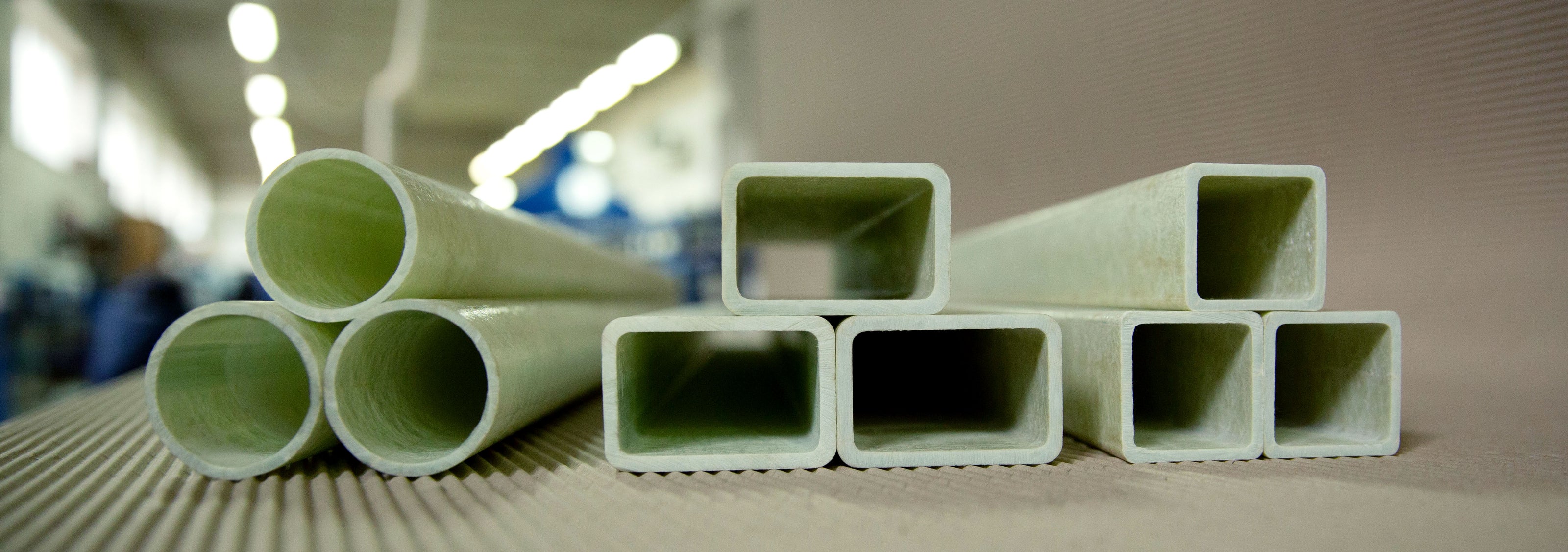

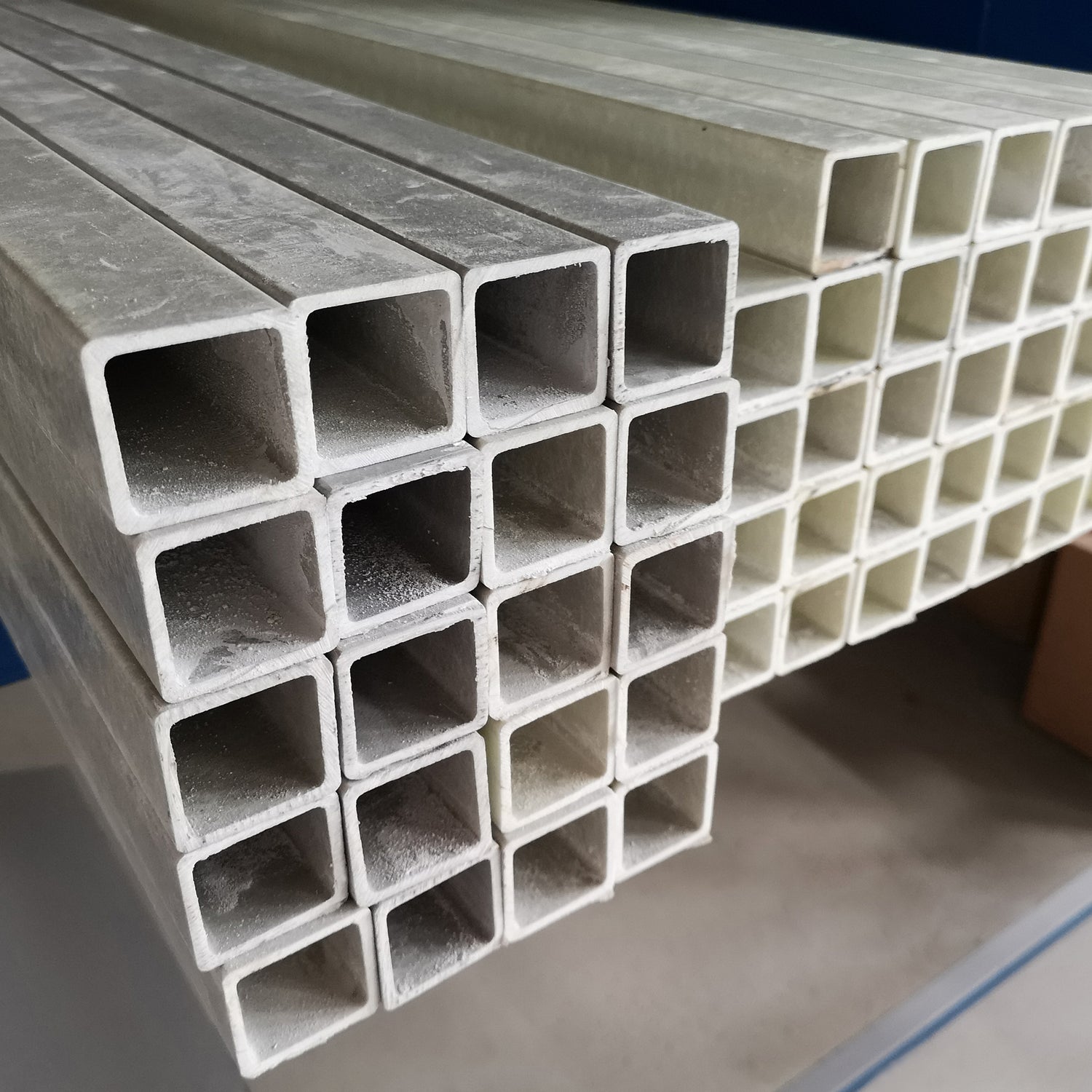

Composit profiles

Galime pasiūlyti stiklo pluošto profilius individualiai Jums pritaikytus pagal vieną ar kelis...

Fiberglass rebar

An excellent choice for foundation and floor reinforcement

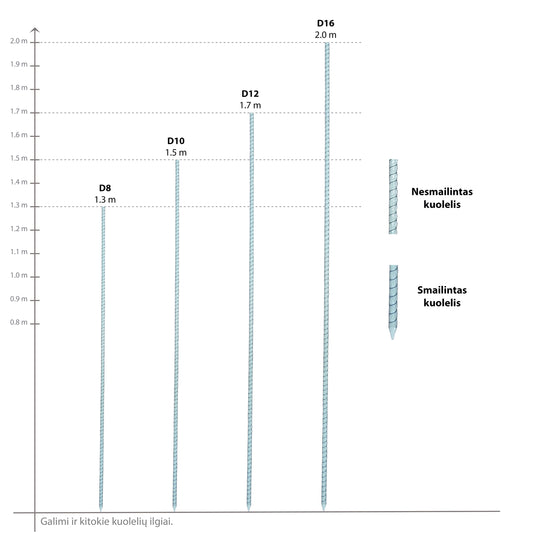

Fiberglass posts

Suitable for portable and stationary enclosures

Fiberglass profiles

Strong, light and durable replacement for steel, wooden and aluminum profiles

BUY NOW

-

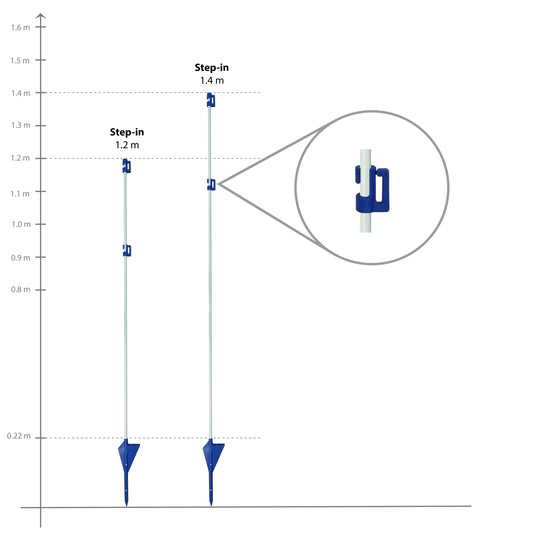

Adjustable clip for wire and tape (D10-12)

Regular price From€0.11 EURRegular price -

Adjustable Insulator for wire and tape (D8-12)

Regular price€0.17 EURRegular price -

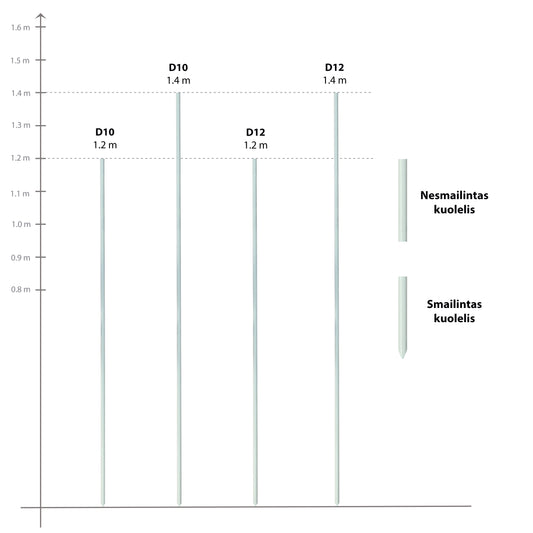

Calibrated fiberglass post

Regular price From€1.48 EURRegular price -

Fiberglass bracket with additional stiffening elements (STV)

Regular price From€3.52 EURRegular price -

Fiberglass rebar

Regular price From€0.25 EURRegular price -

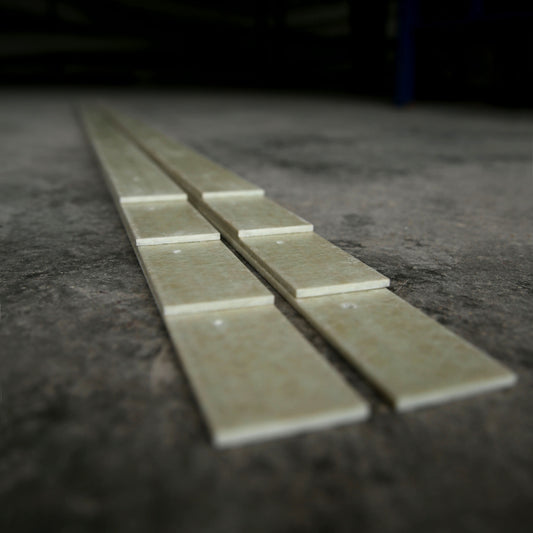

Fiberglass stripe

Regular price From€0.78 EURRegular price -

Fiberglass tube

Regular price From€9.58 EURRegular price -

Ribbed fiberglass post

Regular price From€0.33 EURRegular price